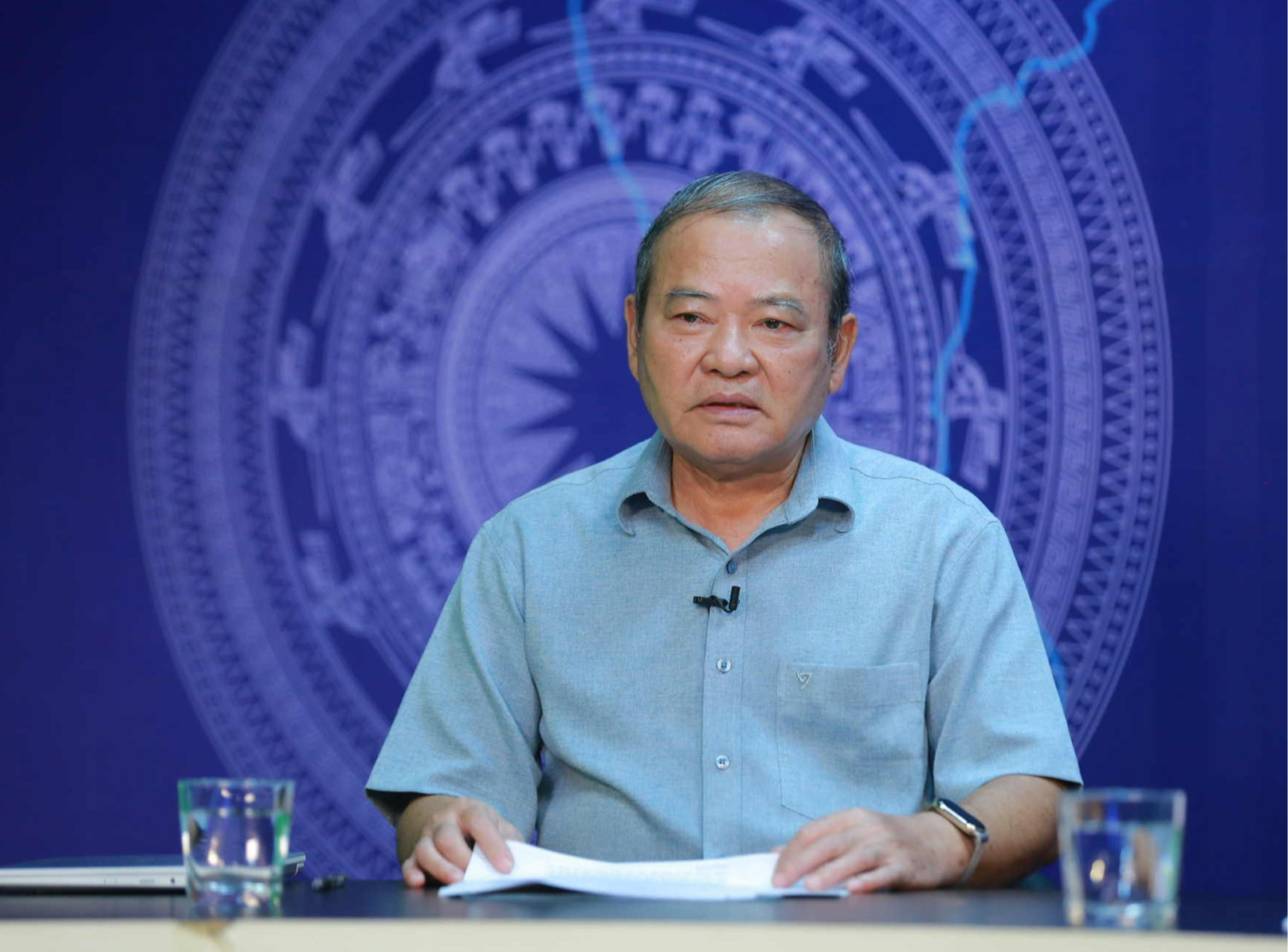

Delegates at the seminar "Localizing the automobile industry with an independent and self-reliant economy ". Photo: Minh Khoi

That was the sharing of experts and delegates at the seminar "Localization of the automobile industry with an independent and autonomous economy" organized by the Government Electronic Information Portal on the morning of September 18, in Hanoi .

Localization rate is still low

Dr. Nguyen Si Dung, former Deputy Head of the National Assembly Office, said that implementing the Vietnam Automobile Industry Development Strategy to 2025, with a vision to 2035, approved by the Prime Minister, over the past 10 years, the Vietnamese automobile manufacturing industry has achieved positive results. However, overall, it has not met expectations and wishes.

Dr. Nguyen Si Dung, former Deputy Head of the National Assembly Office, speaks. Photo: Minh Khoi

The biggest limitations of the Vietnamese automobile manufacturing industry include the low localization rate and the heavy dependence on imported components. Every year, the automobile industry spends nearly 10 billion USD on importing components; the competitiveness of exported products is still weak and in its infancy...

“This leads to trade imbalance, lack of domestic added value, failure to create a domestic supply chain and especially failure to accumulate high-tech production capacity, foreign currency flows abroad. Therefore, developing the automobile industry and especially localization is a very important policy orientation and must be our priority development goal,” Dr. Nguyen Si Dung emphasized.

Dr. Ngo Nhat Thai speaks. Photo: Minh Khoi

Sharing the same view, Dr. Ngo Nhat Thai, an expert with more than 30 years of experience in the automobile manufacturing industry, said that what we are concerned about is the low localization rate, reaching only about 10% for 5-seat cars and small passenger cars.

Although for special-purpose vehicles or trucks and buses, the rate can be higher, up to 40%, achieving the target set by the State until 2020. But the localization rate for Vietnam's passenger cars is too low, especially compared to neighboring countries such as Thailand, Malaysia or Indonesia.

Emphasizing the role of the automobile industry, Dr. Nguyen Van Hoi, Director of the Institute for Strategy and Policy Research in Industry and Trade - Ministry of Industry and Trade, said that in 2024, the total number of automobiles consumed in the Vietnamese market reached 580,000 units, including both imported and domestically assembled products. The forecast of 900,000 to 1 million cars in 2030-2035 is completely feasible, showing a very potential market.

Mr. Nguyen Van Hoi acknowledged that, in the recent reality, there have been both achievements and limitations, therefore, there needs to be orientations in the coming time to truly meet the needs of the automobile market, moving towards 1 million or 900,000 cars of all kinds in the period from now to 2030 and 2035.

From an economic perspective, Prof. Dr. Hoang Van Cuong, National Assembly delegate of Hanoi City, Vice Chairman of the State Council of Professors, said that Vietnam's policy has been well protected with the aim of local production. Vietnam is one of the countries with the highest import tax on cars in the world.

Prof. Dr. Hoang Van Cuong, National Assembly delegate of Hanoi City Delegation, Vice Chairman of the State Council of Professors, spoke. Photo: Minh Khoi i

“However, we have not yet achieved the desired goal of localization. We also have automobile products assembled in Vietnam. It can be said that, production in Vietnam in the sense of assembly is quite a lot, over 10 automobile brands, especially small cars, small trucks, passenger cars, and cars for personal use,” Mr. Hoang Van Cuong analyzed and said that the most worrying thing is that the localization rate of this group is only about 10%, almost zero, not considered localization.

Analyzing further, Dr. Ngo Nhat Thai said that the low localization rate has many reasons. The first reason is that the annual consumption in Vietnam is very low compared to the world's leading automobile manufacturing countries. Every year, both domestic production and import are about 500,000 vehicles, of which 175,000 are imported.

“With such low output and divided into dozens of different brands, not to mention each brand, the quantity per vehicle type is even lower. With low quantity, the ability to invest in the production of localized components is extremely difficult,” Dr. Ngo Nhat Thai said.

Orientation towards "Made in Vietnam" automobile products

Dr. Nguyen Si Dung emphasized that in order to ensure the rapid and sustainable development of the Vietnamese automobile manufacturing industry, and to direct "Made in Vietnam" automobile products to the export market, the Vietnamese automobile manufacturing industry must increase the localization rate of automobile products produced in Vietnam in the true sense. This is an objective requirement and also an urgent and urgent demand.

Dr. Nguyen Van Hoi, Director of the Institute for Industry and Trade Policy and Strategy Research - Ministry of Industry and Trade. Photo: Minh Khoi

To orient the automobile products "Made in Vietnam", Dr. Nguyen Van Hoi said, we must first focus on science and technology, because automobile manufacturing is a special industry, very different from other industries. Therefore, to change, we must first promote scientific and technological breakthroughs to develop all supporting industries of the automobile industry, from the chassis, transmission, gearbox, electronic software...

"We must build centers to support the automobile industry, including other industries such as the automobile supporting industry, which must be large-scale, concentrated, and have fair competition globally," said Mr. Nguyen Van Hoi.

According to Dr. Nguyen Van Hoi, with breakthroughs in science and technology and business experience, Vietnam can completely make all supporting industries for the automobile industry from chassis, shell, lights, turn signals, transmission, steering system... "But on the condition that we have to change in the direction of improvement, that is, we must have different science and technology, because people have already done the old models and old standards," said Mr. Hoi.

From another perspective, Dr. Ngo Nhat Thai believes that it is necessary to review the tax system to adjust each item to the standard, to really stimulate the Vietnamese automobile industry to develop localized production. He gives an example, if 100% of the parts must be imported, how much percentage is for the car body, how much percentage is for the system...

“We have to adjust the ratio appropriately. If the ratio is adjusted appropriately, car manufacturers will focus on localization to reduce tax rates,” Mr. Thai shared.

Delegates said that the National Assembly has amended the Law on Corporate Income Tax and the Investment Law is also under review and amendment. This is a good time for relevant units to discuss and report to the Government and the National Assembly to have policies to attract supporting industries to participate in the chain to increase the localization rate for automobiles and mechanical industries as well as related industries.

Source: https://hanoimoi.vn/o-to-made-in-viet-nam-muon-xuat-khau-phai-tang-ty-le-noi-dia-hoa-716476.html

![[Photo] Closing of the 13th Conference of the 13th Party Central Committee](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/08/1759893763535_ndo_br_a3-bnd-2504-jpg.webp)

Comment (0)