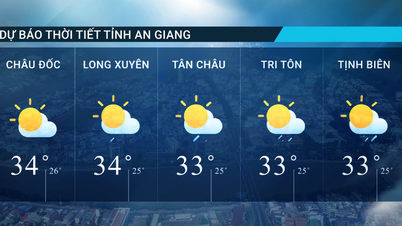

Piloting the model of raising apple snails in the direction of dormancy. Photo: KIM NGAN

According to the Provincial Agricultural Extension Center, there are currently snail products on the market that have undergone a dormant process, known by the commercial name of kitchen-smoked snails. However, the method of making the product is mainly passed down by word of mouth, so there is no common process for producing commercial products.

On that basis, the Provincial Agricultural Extension Center coordinated with Mr. Ngo Tuan Tinh to implement a model to evaluate the effectiveness of allowing apple snails to grow dormant, contributing to increasing product value. The specific goal of the model is to let apple snails grow dormant at a scale of 400 snails/m 2 , achieving a survival rate of 70% or more; profit margin of 50% or more; to build a process for apple snails to grow dormant, increasing product value. This is a model that combines temperature control and nutritional metabolism of snails during dormancy, simulating natural conditions to put snails into a resting state, thereby preserving energy and improving meat quality.

The model was carried out in 2 phases. Phase 1 was temperature acclimation, with the selection of commercial snails over 5 months old, an average of 30 snails/kg. After soaking and cleaning the mud for 3 days, the snails were placed in dry conditions on shelves in a closed room. The temperature was adjusted to about 28 - 32 degrees Celsius for 5 days, 10 days and 15 days with the temperature increasing each day by 1 degree Celsius, 0.5 degree Celsius and 0.33 degree Celsius, respectively, to help the snails gradually adapt and enter a dormant state. In addition, a control shelf was also arranged without applying temperature acclimation to assess the difference in loss rate.

In phase 2, the process lasts 4 months, focusing on the process of nutritional metabolism inside the snail's body when it has entered a dormant state. The snail is brought to an environment outside the closed room, with a rain cover attached with a light-absorbing roof to create color for the snail, the light is adjusted to levels of 24%, 36% and 47%. After that, the snail is rearranged on the shelf frame and a layer of dry straw is used as a substrate to facilitate the snail's self-metabolism.

Currently, the model has shown positive results, with a snail survival rate of 80%. The group of snails acclimatized to temperature has a higher survival rate than the control group, the snails using direct light 24% have beautiful colors, shiny shells and whiter snail meat. The research team is still monitoring the survival rate, weight and sensory factors of the snails. Although still in the testing process, the initial results from the model show the possibility of opening a new direction for snail farming in An Giang , because dormant snails have higher quality and selling price than normal apple snails. Currently, commercial snails on the market cost from 35,000 - 40,000 VND/kg, while dormant snails alone can cost up to 200,000 VND/kg.

This model uses little water, does not cost feed, is suitable for small-scale farmers who want to increase the value of their products. After completing the model, this process can be replicated for farmers in many places to develop household economy and improve their lives.

Silver

(Provincial Agricultural Extension Center)

Source: https://baoangiang.com.vn/nghien-cuu-quy-trinh-nuoi-oc-buou-dong-theo-huong-tiem-sinh-a464790.html

![[Photo] Comrade Nguyen Duy Ngoc visited and worked at SITRA Innovation Fund and ICEYE Space Technology Company](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/23/1761174470916_dcngoc1-jpg.webp)

![[Photo] Da Nang: Shock forces protect people's lives and property from natural disasters](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/22/1761145662726_ndo_tr_z7144555003331-7912dd3d47479764c3df11043a705f22-3095-jpg.webp)

![[Photo] General Secretary To Lam and his wife begin their official visit to Bulgaria](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/23/1761174468226_tbtpn5-jpg.webp)

![[Photo] Award Ceremony of the Political Contest on Protecting the Party's Ideological Foundation](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/22/1761151665557_giaia-jpg.webp)

Comment (0)