Ms. Ramla Khalidi, UNDP Resident Representative in Vietnam and Ms. Hilde Solbakken, Norwegian Ambassador to Vietnam

This is the opinion that Ms. Ramla Khalidi, UNDP Resident Representative in Vietnam and Ms. Hilde Solbakken, Norwegian Ambassador to Vietnam, exchanged with the Government Electronic Newspaper.

New solutions for urgent challenges

As countries around the world are facing the twin challenges of climate change and plastic pollution, new solutions are needed, according to Ramla Khalidi and Hilde Solbakken. Co-processing is one such solution, increasingly recognized as a powerful tool in the transition to a circular economy .

This technology uses non-recyclable waste to replace fossil fuels and raw materials in energy-intensive industries, such as cement production. Co-processing can help treat non-recyclable waste, reduce dependence on fossil fuels and cut emissions.

For developing countries with increasing waste volumes, such as Vietnam, co-processing is a fast-acting and practical solution – provided it is implemented as part of a comprehensive approach to waste management, including reduction, reuse and recycling, supported by strong regulations and regular monitoring.

"Win-win" solution

First of all, in terms of the environment , co-processing allows the destruction of difficult-to-recycle waste in a cement kiln at temperatures above 1,450°C, ensuring complete destruction of pollutants without creating residual ash and slag like waste-to-electricity (WtE) technology.

Economically , this is a cost-effective solution. Businesses can reduce fuel costs by replacing coal with waste, while local authorities take advantage of existing cement plant infrastructure, without having to invest in new waste treatment facilities.

From a climate perspective , co-processing contributes to reducing greenhouse gas emissions by replacing fossil fuels. In fact, in Europe, up to 75% of traditional fuels in the cement industry have been replaced by waste. India has also achieved remarkable results by expanding the application of this solution.

Waste is brought into the furnace at Lam Thach Cement factory. Photo: Ximang.vn

Scientific basis and international experience

According to research by SINTEF (Norway), cement kilns can safely destroy persistent organic pollutants. Dr. Kåre Helge Karstensen, Head of the SINTEF Scientific Research Group and Head of the OPTOCE project (Turning Ocean Plastics into Opportunities in the Circular Economy), emphasizes:

“Vietnam is investing in developing WtE plants (1,400 MW planned), but co-processing in cement kilns offers a faster, cheaper solution to reduce coal use, prevent waste leakage and promote circular economy goals. It avoids the environmental risks associated with incineration and, if properly managed, does not produce ash or toxic emissions.”

However, for successful implementation, it is necessary to have: A strict legal framework and monitoring mechanism to ensure safe operation. A continuous, transparent and independently verified monitoring system to strengthen community trust.

A piece in the circular economy puzzle

Co-processing is not a “magic wand”, but rather part of an overall waste management strategy, along with reduce, reuse and recycle. It is particularly useful for residual waste – which cannot be recycled – helping to reduce reliance on landfill and make efficient use of resources.

Vietnam generates nearly 4 million tons of plastic waste each year, most of which cannot be recycled and is at high risk of being buried or leaked into the environment.

Provinces like Quang Ninh, which is considering waste-to-energy incineration, have the opportunity to consider a combination of solutions to treat different waste streams.

With several cement plants operating in the province, co-processing could become a practical solution that effectively coordinates with the province’s waste-to-energy plan, providing a faster, more cost-effective approach to reducing reliance on landfills and cutting emissions.

“Our collaboration in Quang Ninh has demonstrated this potential,” said Ms. Ramla Khalidi and Ms. Hilde Solbakken. “Over the years, UNDP and the Norwegian Embassy have worked with Quang Ninh on solid waste management, including source separation, recycling promotion, support for informal workers, and piloting co-processing at Lam Thach Cement Factory. This experience shows that technical solutions can be successfully integrated into inclusive, community-based approaches.”

Quang Ninh provincial leaders have demonstrated a clear vision for waste management and greenhouse gas emissions reduction. Co-processing in cement kilns could provide the province with an effective tool to achieve these goals faster and at lower cost.

According to Ms. Ramla Khalidi and Ms. Hilde Solbakken, with the support of UNDP, Norway and other partners, Quang Ninh can absolutely become a model of circular waste management, harmoniously combining elements of innovation, environmental protection and economic efficiency.

Looking to the future

Co-processing is not a “magic wand”. But, as part of a broader circular economy and waste management solution, it can play an important complementary role.

When combined with waste-to-energy, expanded recycling and source-based waste reduction, co-processing offers Vietnam a faster and more cost-effective way to turn residual waste into resources.

The UNDP Resident Representative in Vietnam and the Norwegian Ambassador to Vietnam jointly affirmed their desire to " continue dialogue and cooperation, accompanying Vietnam on the journey towards a greener, cleaner and more sustainable future ".

Source: https://baochinhphu.vn/dong-xu-ly-giai-phap-moi-cho-thach-thuc-kep-tai-viet-nam-102251003111241254.htm

![[Photo] Students of Binh Minh Primary School enjoy the full moon festival, receiving the joys of childhood](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/3/8cf8abef22fe4471be400a818912cb85)

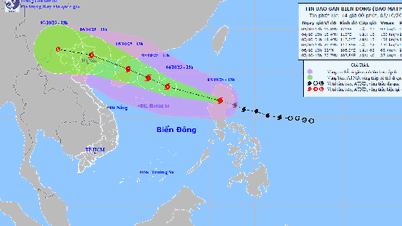

![[Photo] Prime Minister Pham Minh Chinh chairs meeting to deploy overcoming consequences of storm No. 10](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/3/544f420dcc844463898fcbef46247d16)

![[Infographic] What are the growth targets of Dong Nai province in the first 9 months of 2025?](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/10/3/45f9330556eb4c6a88b098a6624d7e5b)

Comment (0)