According to Gizmochina , SMIC is said to have developed second-generation 7nm chip technology that can be used to produce smartphone chips. Not stopping there, the company is currently pursuing research on 5nm and 3nm chip manufacturing technology.

SMIC is looking to make a breakthrough by producing 3nm chips with DUV machines.

The research is being conducted internally by the company's R&D team and is led by co-CEO Liang Mong-Song, a renowned semiconductor scientist who has worked at TSMC and Samsung and is considered one of the brightest minds in the semiconductor industry.

This means that the current constraints cannot completely stop SMIC's progress in developing more advanced chips than 7nm. It simply slows the company's progress, although a combination of factors has helped SMIC overcome the challenges.

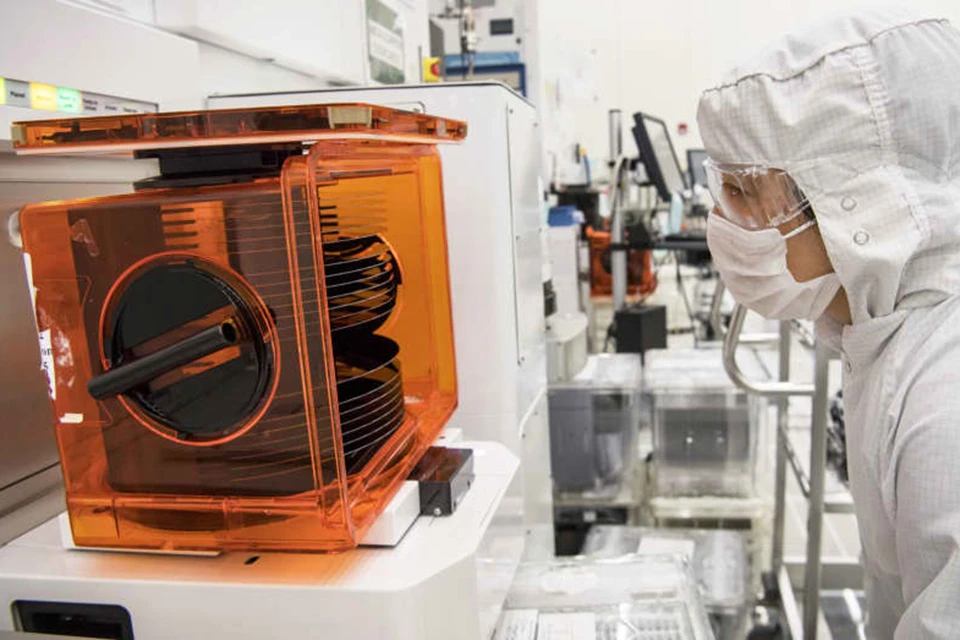

SMIC, currently the fifth-largest contract chipmaker in the industry, has lost access to the most advanced wafer manufacturing tools, severely limiting its ability to adopt new process technologies. Specifically, due to US sanctions, the company cannot get extreme ultraviolet (EUV) lithography machines from ASML, and is limited to deep ultraviolet (DUV) lithography for its second-generation 7nm chip manufacturing process.

The ASML Twinscan NXT:2000i lithography machine is SMIC's best tool yet. It can etch at a manufacturing resolution of up to 38nm, a level of precision sufficient to produce patterns for 7nm chips. ASML and IMEC say that to produce 5nm and 3nm chips, the required manufacturing resolutions will be 30-32nm and 21-25nm, respectively.

To achieve sub-7nm chip production without EUV, SMIC will need to adopt a complex multi-patterning process, which can affect yield and wear down manufacturing equipment. The cost of using multiple patterns is also quite high. Despite that, SMIC is determined to move towards 3nm chip production. If successful, 3nm chip production using only DUV will be an important milestone for the Chinese manufacturer.

Source link

![[Photo] Students of Binh Minh Primary School enjoy the full moon festival, receiving the joys of childhood](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/3/8cf8abef22fe4471be400a818912cb85)

![[Photo] Prime Minister Pham Minh Chinh chairs meeting to deploy overcoming consequences of storm No. 10](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/3/544f420dcc844463898fcbef46247d16)

Comment (0)