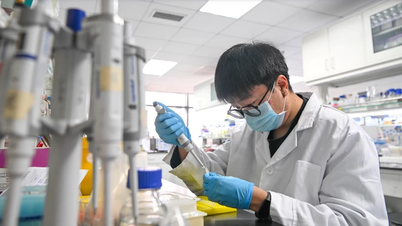

Scientists at the University of Nottingham (UK) have just identified the microbial and environmental factors that determine chocolate flavor during the fermentation process of cocoa beans - the first and most important step after harvest, laying the foundation for aroma, flavor complexity and reducing bitterness.

Research published in the journal Nature Microbiology on August 18 shows that temperature, pH and microbial communities interact with each other during the fermentation process, thereby forming the chocolate flavor.

The research team identified the microbial species and metabolic characteristics associated with “premium” chocolate, and demonstrated that both abiotic (temperature, pH) and biotic (microbial) factors are stable predictors of flavor development.

According to Dr. David Gopaulchan, lead author of the study, cocoa fermentation is a natural process driven by microorganisms, which usually takes place directly on the farm when beans are piled in bins, baskets or compost heaps.

Under these conditions, natural bacteria and fungi from the environment will decompose the beans, creating chemical compounds that determine the final taste and aroma of the chocolate.

However, this process is spontaneous and difficult to control, resulting in variable grain quality between seasons, farms or regions.

To find a way to recreate this process sustainably, scientists worked with Colombian farmers to monitor natural fermentation, identify factors that influence flavor, and then put them into the lab.

Here, they create a “defined microbial community” – a collection of selected bacteria and fungi – that can replicate the chemical and sensory characteristics of traditional fermentation. The resulting chocolate retains the same premium flavor profile as on the farm.

“We have shown that based on measurable parameters such as pH, temperature and microbial variability, producers can predict and maintain consistent flavor,” Dr. Gopaulchan emphasized. “This is a shift from spontaneous fermentation to a standardized, science-based process, just as yeast strains revolutionized the beer and cheese industries.”

According to the research team, “domesticating” the cocoa fermentation process opens a new era for the chocolate industry: using standard “starter” yeast to ensure consistent quality, develop new flavors and elevate global chocolate./.

Source: https://www.vietnamplus.vn/dau-la-bi-mat-giup-tao-nen-huong-vi-chocolate-hao-hang-post1057150.vnp

![[Photo] Solemn opening of the 12th Military Party Congress for the 2025-2030 term](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/2cd383b3130d41a1a4b5ace0d5eb989d)

![[Photo] General Secretary To Lam, Secretary of the Central Military Commission attends the 12th Party Congress of the Army](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/9b63aaa37ddb472ead84e3870a8ae825)

![[Photo] Panorama of the cable-stayed bridge, the final bottleneck of the Ben Luc-Long Thanh expressway](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/391fdf21025541d6b2f092e49a17243f)

![[Photo] President Luong Cuong receives President of the Cuban National Assembly Esteban Lazo Hernandez](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/4d38932911c24f6ea1936252bd5427fa)

![[Photo] The 1st Congress of Phu Tho Provincial Party Committee, term 2025-2030](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/1507da06216649bba8a1ce6251816820)

![[Infographic] Key tasks in the 2025-2030 term of Dong Nai province](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/9/30/59bd43f4437a483099313af036fef0db)

Comment (0)