Night fell, another day of March gradually came to an end, the target of opening to traffic was less than 50 days away. Halfway up Shenwu Mountain, the sound of machinery became more intense. The work teams that had been changing shifts since 6pm were still working, although they were somewhat tired.

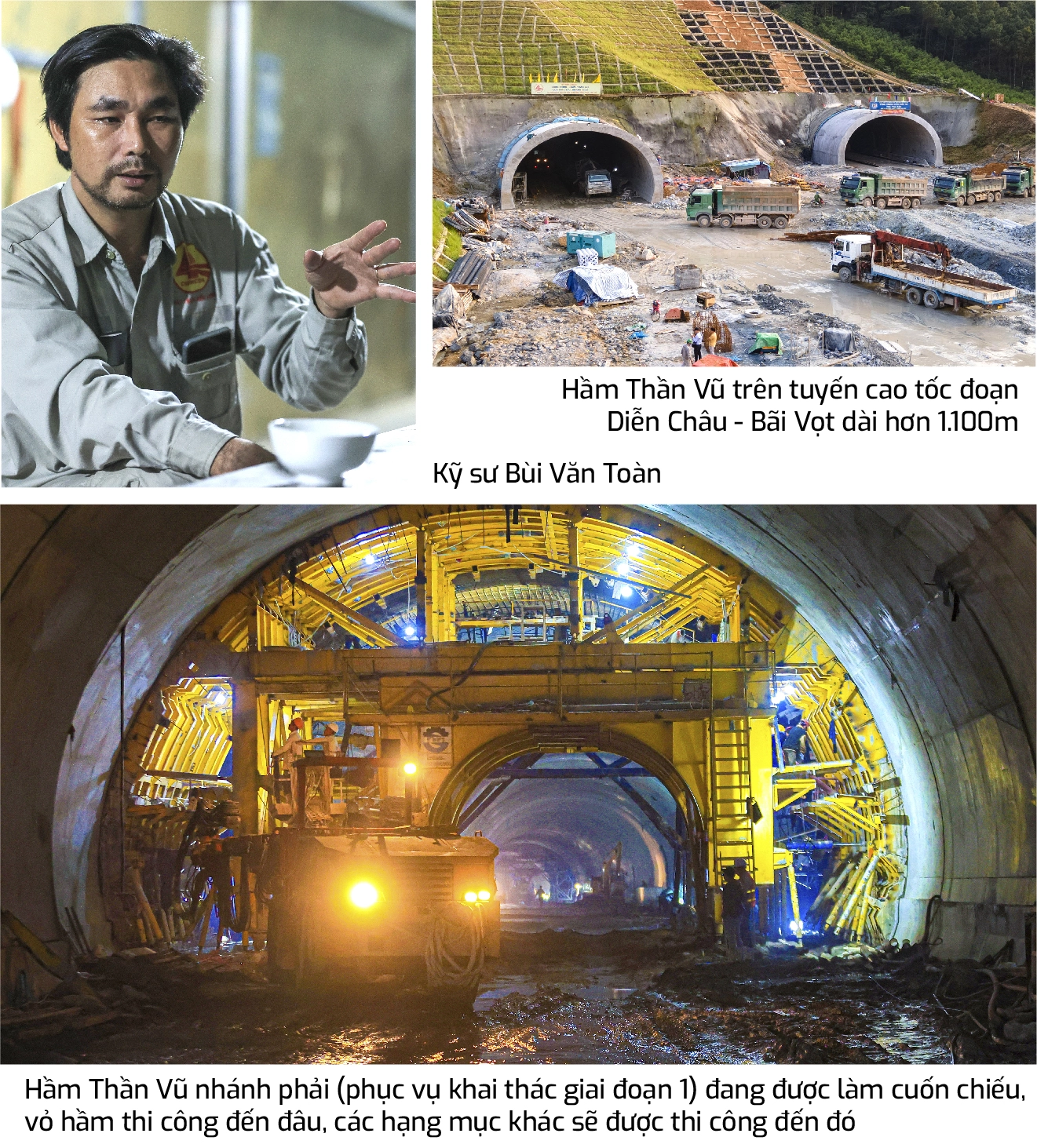

Returning from the northern tunnel entrance to a corrugated iron room less than 10 square meters deep at the end of the workers' shed, engineer Bui Van Toan, Commander of the Than Vu tunnel construction of Cienco4 Group, took off his dusty protective suit and quietly walked to the table outside to drink water so as not to disturb the sleep of his colleague in the bed next to him.

"There are many difficulties. But what I thought was impossible is almost done," said Mr. Toan.

Engineer Bui Van Toan disseminates the plan to workers before starting their shift.

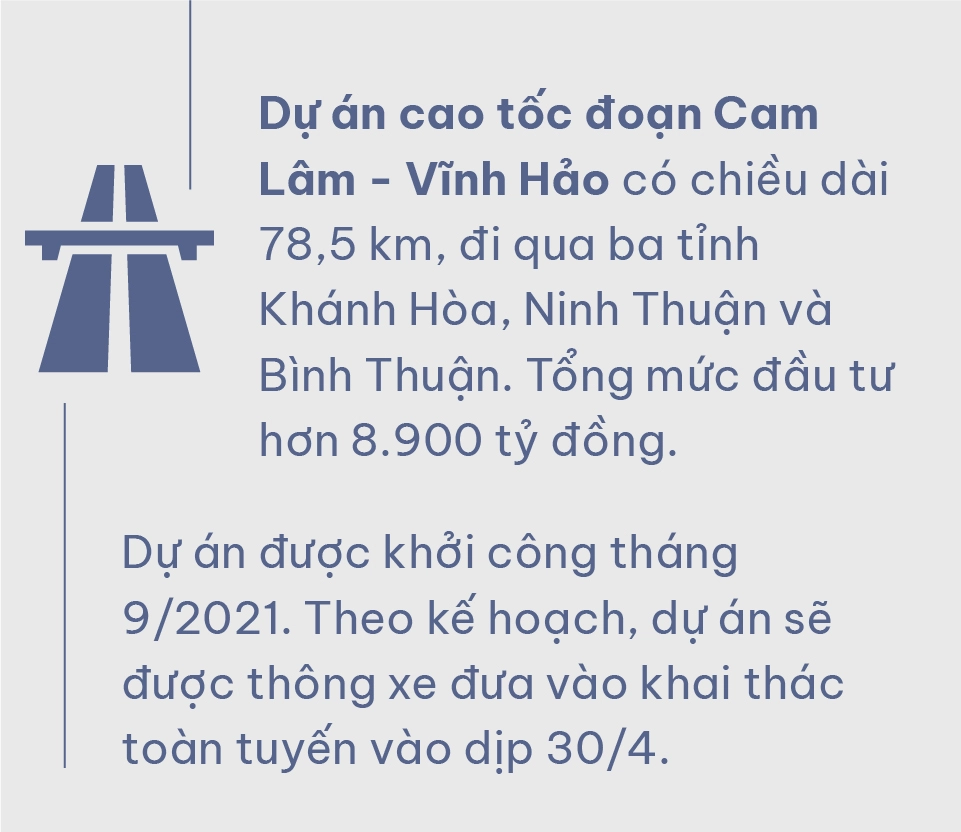

Participating in the construction of the 567m left tunnel branch on the North side, he said that while most other tunnel projects usually have the tunnel door opened at the foot of the mountain, the starting point of the Than Vu tunnel door is halfway up the mountain.

Geology is constantly changing, survey assessment is not accurate, there are segments assessed as hard rock, in fact the rock is easy to fall.

The most stressful moment was when digging to the middle of the tunnel (around June 2023), many mentally weak workers refused to reinforce the tunnel dome when they saw several cases of falling rocks even though no serious incidents had occurred.

Colonel Le Minh Duc checks the construction technique of steel reinforcement before pouring concrete on the Than Vu bridge deck.

"They are right to ask for adequate safety before working. But what is absolute safety? How should I explain to them? With the highest position at the site, I stood up to make a commitment that if any problem occurs, I will take full responsibility before the law," said Mr. Toan, adding that thanks to that, workers gradually returned to the construction sites.

The digging steps were also more careful and meticulous. According to the original plan, if everything went well, the contractor could dig 3m per day, but due to the difficult geology, the average speed was only about 1m/day. On October 5, 2023, the last blast safely exploded, and everyone felt relieved, ending the days of fear, not knowing when the risk would strike.

Mr. Vo Son Hai, Commander of Hoa Hiep Company Limited, also admitted that working through weak ground is the most nerve-wracking time: "There was a case where the brothers were building an arch, and just took a few steps back when a large rock fell down. Luckily, everyone was okay, but it is estimated that about 10% of the workforce quit afterward because they were so scared."

Weak geology is also the bottleneck that caused the construction of Nui Vung tunnel on the Cam Lam - Vinh Hao expressway (the longest tunnel of the 6 mountain tunnels in the North - South expressway project, Eastern region, phase 1) to continuously stop construction from December 2022 to June 2023.

The construction process of Nui Vung tunnel encountered weak geology, for 4 consecutive months, construction had to be stopped many times to optimize construction solutions and ensure safety.

Mr. Dang Tien Thang, Deputy General Director of Cam Lam - Vinh Hao Joint Stock Company, said that the geology in the southern tunnel was so complex that at the end of the excavation, there were places where water gushed out like a "waterspout", and an 18-liter paint bucket filled with water in just a split second.

"That difficulty forced us to choose: stop construction, slow down progress, continue digging or accept the risk. While working and searching for solutions, the progress of digging the southern tunnel slowed down. If the northern tunnel can dig 3m per day, the southern tunnel can only dig 1m in 3 days," Mr. Thang said, adding that Deo Ca Group has increased resources to speed up the progress of the northern tunnel.

The digging step is calculated to be longer, the implementation cycle is optimized. If normally the steps of drilling, blasting, loading, reinforcing, and transporting out take about 24 hours, all must be accelerated to 20 hours. Previously, a drilling and blasting cycle could only drill 100m3, and the acceleration time had to be calculated to increase by a few dozen cubic meters.

When the tunnel was closed, the South side was dug about 350m and the North side was dug about 1,800m instead of each end digging half the tunnel length as originally planned. Thanks to that solution, by August 2023, Nui Vung tunnel was dug through.

"If I were to write a memoir, it would probably take me about 6 months to tell about the construction journey on the Cam Lam - Vinh Hao expressway section," Mr. Nguyen Van Ngoi, Deputy General Director of Construction Investment Corporation 194 (Company 194) confided while slowly walking on the road leading to the executive office.

Approaching the project from the early days, Mr. Ngoi was impressed with the construction time of the two largest overpasses of the project. "This is the Km55+982 bridge", pointing to the middle pillar of the bridge, Mr. Ngoi said that the construction of bored piles is an extremely stressful item.

In this area, the rock is hard, at the beginning of construction, the conventional drilling method could only work for a while before the drill bit broke. No less than 5 units came in and drilled one pile and then gave up, the investor did not continue even if he paid more money. It took 3 months to find all kinds of solutions, success only came with the solution of using a larger drill, higher rpm, and a more special drill bit.

For Mr. Tran Nam Trung, General Director of Company 194, the most memorable memory is the Km60 bridge. The bridge is located in the valley between two high mountains. According to the approved construction method (longitudinal beam launching), it takes 1 month to complete 1 span, which means it will take 22 months to construct 22 spans and the bridge will be completed around June 2024.

To optimize progress, Company 194 changed the solution from vertical to horizontal launching. The contractor widened the service road, brought the 60-70 ton girders down to the bridge pier area, and used two 350- and 450-ton cranes to lift them up, with an average speed of 3 days/span. Thanks to that, in less than 18 months, the bridge was completed, meeting the traffic opening time on April 30, 2024.

The overpass at Km 60+552 has the highest pillar (over 47m) on the Cam Lam - Vinh Hao expressway, designed with a length of 883m, 21 pillars, 22 spans and has been completed.

Boldly changing construction solutions is also the direction that helps Truong Son Construction Corporation optimize the construction time of 2/4 of the largest terrain overpasses of the North-South expressway project, Dien Chau - Bai Vot section.

Standing on Than Vu 2 bridge - the longest overpass of the project (1,300m), Colonel Le Minh Duc, Executive Director of XL2 package, said that according to the initial plan, the construction of beams and bridge deck will be deployed from the middle to both ends.

During the construction process, realizing that the Than Vu tunnel end had a longer construction length, the contractor improved the method, doubling the construction line instead of just one.

Than Vu 2 Bridge is the longest overpass (nearly 1,3000m) on the Dien Chau - Bai Vot expressway, consisting of 31 pillars, 2 abutments with 32 spans and 224 beams.

The 70-80 ton girders are not transported on the road but are lifted from the casting yard below and moved on the bridge deck. The working capacity is increased to 5 spans/month compared to 2.5 spans/month compared to the original measure.

"If not calculated soon, the construction time can be extended by at least another 1.5 months, that is, until May or June 2024 to complete. With the characteristics of a high, long, and large-volume bridge, initially, Than Vu 2 Bridge was a project that many units did not dare to accept," said Colonel Duc.

At Than Vu 2 Bridge, 346 bored piles with a total length of about 6,000m were constructed on a geological terrain of rock, which was a huge challenge. Some piles were 7m long and took 7 days to complete. That is why the goal of completing bored piles in 6 months was set, which no one dared to believe.

Source

![[Photo] The 1st Congress of Phu Tho Provincial Party Committee, term 2025-2030](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/1507da06216649bba8a1ce6251816820)

![[Photo] General Secretary To Lam, Secretary of the Central Military Commission attends the 12th Party Congress of the Army](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/9b63aaa37ddb472ead84e3870a8ae825)

![[Photo] General Secretary To Lam receives US Ambassador to Vietnam Marc Knapper](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/29/c8fd0761aa184da7814aee57d87c49b3)

![[Photo] Solemn opening of the 12th Military Party Congress for the 2025-2030 term](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/2cd383b3130d41a1a4b5ace0d5eb989d)

![[Photo] General Secretary To Lam attends the ceremony to celebrate the 80th anniversary of the post and telecommunications sector and the 66th anniversary of the science and technology sector.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/29/8e86b39b8fe44121a2b14a031f4cef46)

Comment (0)