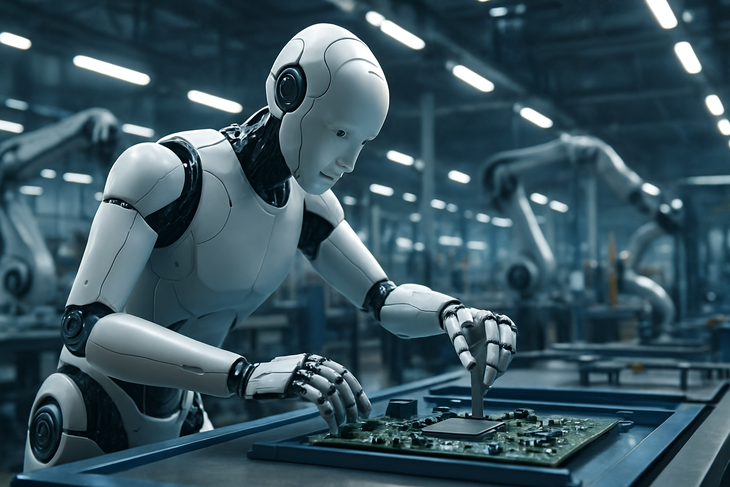

Robots assist humans in production stages at factories

Nvidia and Foxconn are teaming up to implement a new production model by introducing humanoid robots into the server assembly process at a factory in Houston, USA. This is not only a technology test, but also an important step in the roadmap to build a smart factory using robots to serve the AI industry.

Scheduled to begin in the first quarter of 2026, the project raises big questions about the role of humans in modern production lines.

What is special about the factory in Houston?

Foxconn chose the new Houston factory to deploy the humanoid robots because it was built specifically to assemble Nvidia servers, specifically the GB300 series. With its large space and lack of constraints from legacy processes, the factory was an ideal place to test new manufacturing technologies.

Instead of choosing long-standing factories in Asia, Foxconn prioritized a completely new location to easily integrate robots from the beginning. The GB300 server is also a product with high standard design, suitable for robots to perform repetitive operations with good precision.

According to Foxconn representatives, the first phase will focus on robots handling simple steps such as assembling processors, attaching wires and conducting preliminary component inspections. If this process goes smoothly, the robot system will be expanded to take on more complex steps in the future.

Robot's first day at work

In the initial phase, humanoid robots will undertake assembly steps that are considered simple but require high precision such as picking up components, assembling processors, threading wires and attaching power sources. These are repetitive operations with high stability, very suitable for the current capabilities of robots.

Unlike fixed industrial robots, Foxconn's new generation of robots can move around the factory, using computer vision to locate components and coordinate with other equipment.

Foxconn is currently developing two versions of the robot: one with wheels for fast, cost-effective movement, and one with legs that mimic human walking to accommodate more diverse terrain.

The big difference is that these robots are not programmed to perform each task in a fixed manner. Instead, they are trained through simulations in virtual environments, where they learn how to handle components, coordinate operations, and adapt to three-dimensional situations.

Thanks to the artificial intelligence platform behind it, the robot can adjust itself to every small change in the process without reprogramming, thereby improving its adaptability when put into practice.

Once they get used to the task, robots can not only help relieve the load of humans, but also expand the scope of work in the future. With enough training time and real-world data, they can take on more complex assembly steps, check the quality of finished products, or work in groups to complete entire devices.

This marks the beginning of a new phase in smart manufacturing, where robots are no longer an auxiliary arm but a key component of the production line.

Isaac and GR00T: the intelligent duo helping robots learn

For humanoid robots to enter the factory and do real work, the core is not the robotic arm but the artificial intelligence platform behind it. Foxconn has equipped the robot with an AI system called Isaac developed by Nvidia. This is a platform that allows robots to learn through simulation before actual operation.

By practicing in a virtual environment, robots can get used to assembly operations, threading wires, recognizing components and coordinating with other equipment as soon as they enter the real production line.

Nvidia also developed an AI model called GR00T to increase the robot's adaptability. GR00T helps robots observe, understand language and act flexibly in three-dimensional space. Thanks to that, robots do not need to be programmed step by step but can learn from new data, adjust themselves when the production process changes and handle situations that arise in modern factories.

Every robot’s activity is recorded, analyzed, and shared in real time. When a robot makes a mistake, the model is updated so that other robots in the same family can learn from it.

With continuous training mechanisms, group learning capabilities and powerful artificial intelligence platforms, humanoid robots are gradually becoming a real productive force in the AI era.

From small experiments to big changes

Nvidia CEO Jensen Huang has said that humanoid robots will be widely used in manufacturing in less than five years, emphasizing that the field is the ideal environment because of its well-defined and well-controlled tasks. This is a strong commitment from Nvidia, revealing its ambition to make that a reality.

Source: https://tuoitre.vn/robot-lam-viec-trong-nha-may-buoc-ngoat-tu-foxconn-va-nvidia-20250623142219529.htm

![[Photo] Solemn opening of the 12th Military Party Congress for the 2025-2030 term](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/2cd383b3130d41a1a4b5ace0d5eb989d)

![[Photo] Panorama of the cable-stayed bridge, the final bottleneck of the Ben Luc-Long Thanh expressway](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/391fdf21025541d6b2f092e49a17243f)

![[Photo] President Luong Cuong receives President of the Cuban National Assembly Esteban Lazo Hernandez](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/4d38932911c24f6ea1936252bd5427fa)

![[Photo] General Secretary To Lam, Secretary of the Central Military Commission attends the 12th Party Congress of the Army](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/9b63aaa37ddb472ead84e3870a8ae825)

![[Photo] The 1st Congress of Phu Tho Provincial Party Committee, term 2025-2030](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/1507da06216649bba8a1ce6251816820)

Comment (0)