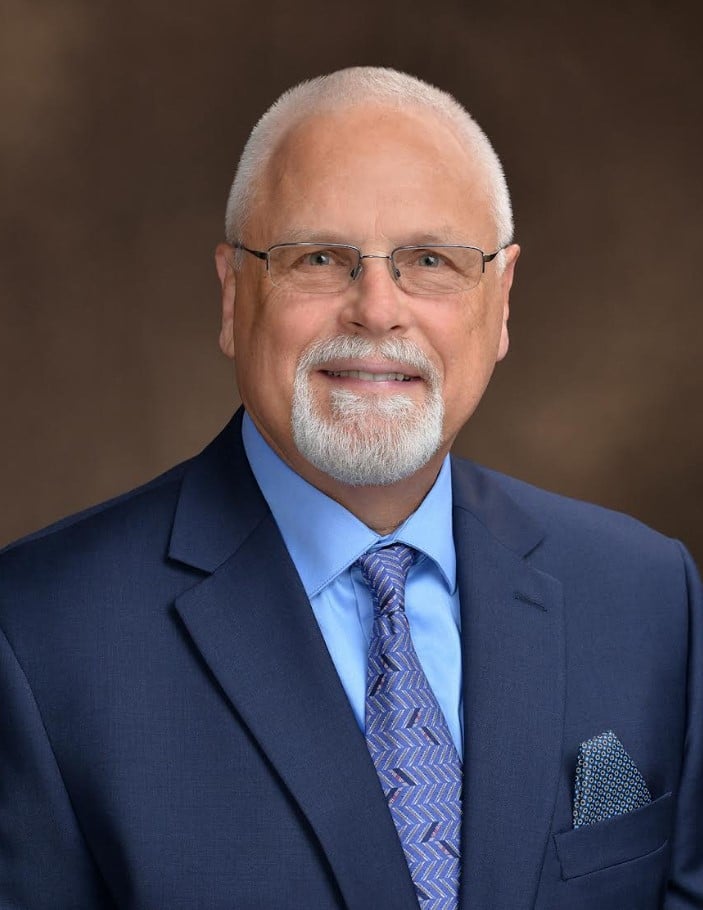

Why is Ethernet 1.6T a key factor in the future of AI and data centers, sir?

Mr. Charles Seifert: The more bandwidth is provided, the lower the volume and latency of data transmission.

Keysight recently helped AT&T achieve a breakthrough in data transmission by successfully transmitting 1.6 Tbps of data on a single wavelength over a distance of 296 km in a commercial fiber optic cable connecting Newark and Philadelphia in the United States. The test signal was transmitted in parallel with existing live traffic on 100 Gbps and 400 Gbps wavelengths, quadrupling network speeds without interruption.

By reducing space and power consumption per transmitted bit by up to 50%, this advancement provides a more environmentally friendly solution for expanding network infrastructure, while breaking records and setting new industry standards, better meeting the ever-increasing demand for faster and more reliable network connectivity.

The ultimate goal of 1.6T Ethernet is to enable ultra-high-speed data transmission for AI data centers—a critical factor in the context of hyperscale machine learning models that require ultra-high-speed performance to operate successfully. Network designers using GPUs and hyperscale AI infrastructure all want one thing—reliability . Reliability that all their network connections will meet the demands of real-time AI processing with the highest reliability. Testing is the foundation for this reliability.

So what are the biggest challenges in 1.6T connectivity validation?

Charles Seifert: Essentially , the challenge is to ensure that every component of the signal chain, from the signal controller chips to the optical components that transmit the signal, meets stringent performance and compliance requirements. This approach involves deep validation of the physical layer, including electrical signal integrity and optical waveform analysis, and must be performed before any optical transceiver is assembled.

Once these components are integrated into the 1.6T transceiver, the testing process continues. The entire module is re-characterized to verify bit error rate performance, forward error correction (FEC) efficiency, and overall Ethernet compliance. Not only does it need to be “qualified,” the hardware must be reliable, high-performance, and flexible enough to support the various Ethernet speeds and applications on the network.

That's why we've built a dedicated solution to simulate real-world network conditions. Our Ethernet 1.6T Network and Link Performance Tester sends traffic through the transceiver and analyzes Layer 1 to Layer 2 performance—including digital Layer 1 and Layer 1.5—to help network designers predict transceiver performance before deployment.

The key is understanding at scale . Proactively understanding transceiver performance under real-world operating conditions with real-time, high-resolution validation helps network designers gain confidence at scale—a factor that is especially important as companies prepare to deploy tens of thousands or even millions of high-tech Ethernet ports across their infrastructure.

What role does software play in simplifying the validation process of complex connections?

Mr. Charles Seifert: Today, engineers must use many different devices to measure, monitor, and re-measure without effective tools to manage or automate this process.

Keysight’s Interconnect Test System (ITS) software solves these challenges by making validation a simple and intelligent process. The centralized Interconnect Library automatically captures, stores, and organizes detailed test data for each interconnect. This allows them to easily access historical test data, compare test results across devices, and manage more configurations with confidence.

The software also allows users to create and manage automated tests. With just a few inputs via a browser interface, engineers can create test scripts and execute consistent, reproducible tests across multiple settings. This process reduces manual work and increases test coverage and speed, providing key advantages in R&D and production environments.

In addition to automation, we also integrate measurement capabilities such as FEC measurement via BERT, which is particularly useful in identifying and debugging signal integrity issues during manufacturing or final assembly. These capabilities enable validation of connection performance in terms of speed, accuracy, and reliability, at scale.

This approach reduces complexity, improves traceability, and supports automation, redefining how conformity assessment engineers perform their work. It transforms a traditionally slow and fragmented process into one that is agile, scalable, and future-ready.

What other challenges will engineers face in the future when validating high-speed Ethernet?

Charles Seifert: Keysight is working with most standards bodies and silicon chip manufacturers, fiber optic interconnects, and copper cabling using electrical 224Gb/s interfaces globally to accelerate the development of the 800GE and 1.6T AI network infrastructure ecosystem. Our 1.6T and 800GE hardware platforms, combined with ITS software, enable performance evaluation of mission-critical interconnects and significantly improve the productivity of test systems. This solution provides our customers with the tools they need to deploy highly reliable and resilient solutions on the network. We demonstrated both products at the OFC Conference in San Francisco in early April .

At OFC 2025 , a demonstration of the results of an early joint development between Keysight, NTT Innovative Devices, and Lumentum – also took place, achieving a new record optical data rate of 448 Gbps per lane. This result will facilitate the development of a power-efficient 3.2T interface for future cloud infrastructure in data center networks, optimized for AI and ML applications requiring ultra-fast/real-time data processing.

As Ethernet speeds increase and new standards emerge more rapidly, rapid and comprehensive component validation becomes increasingly critical. That’s why test systems must support both physical and digital validation, helping teams ensure products are functional, compliant, and ready for production. These solutions can deliver fast, consistent, and accurate measurements across the ecosystem, enabling reduced risk, accelerated innovation, and confidence for manufacturers to scale.

Thank you!

Source: https://doanhnghiepvn.vn/kinh-te/kinh-doanh/vai-tro-cua-ethernet-1-6t-trong-tuong-lai-cua-ai/20250704015533275

![[Photo] President Luong Cuong receives President of the Cuban National Assembly Esteban Lazo Hernandez](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/4d38932911c24f6ea1936252bd5427fa)

![[Photo] General Secretary To Lam, Secretary of the Central Military Commission attends the 12th Party Congress of the Army](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/9b63aaa37ddb472ead84e3870a8ae825)

![[Photo] Solemn opening of the 12th Military Party Congress for the 2025-2030 term](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/2cd383b3130d41a1a4b5ace0d5eb989d)

![[Photo] The 1st Congress of Phu Tho Provincial Party Committee, term 2025-2030](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/30/1507da06216649bba8a1ce6251816820)

![[Photo] General Secretary To Lam receives US Ambassador to Vietnam Marc Knapper](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/29/c8fd0761aa184da7814aee57d87c49b3)

Comment (0)